OEM vs ODM Manufacturing - Differences, Benefits, and Limitations

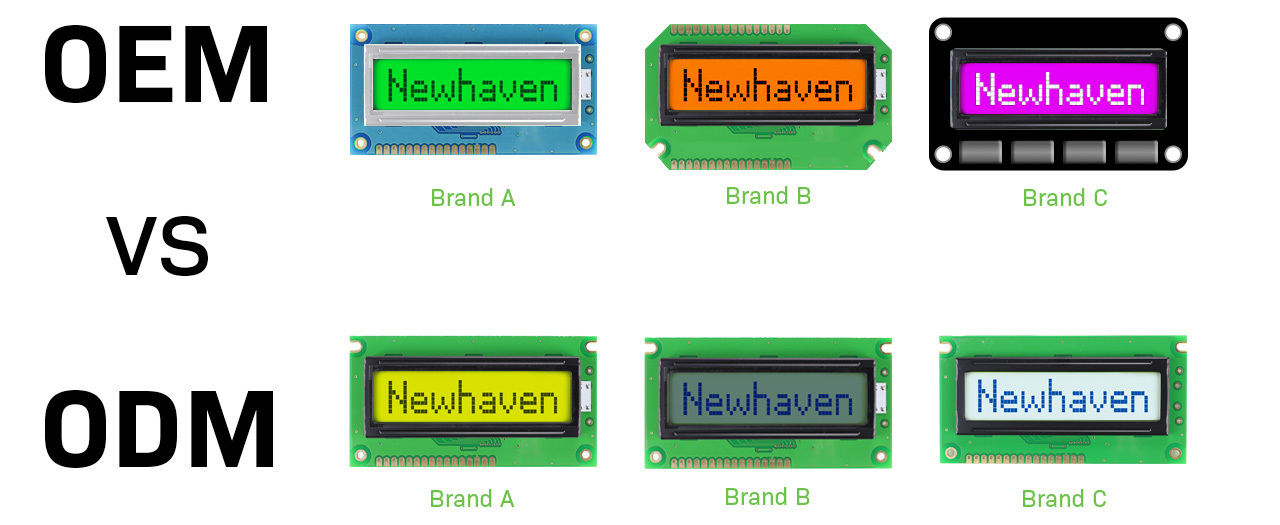

When outsourcing manufacturing, two terms come across: OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer). OEMs create products based on client specifications, whereas ODMs take on some or all design responsibilities before manufacturing for their clients. In this article, we discuss the differences and advantages of these two types of manufacturers.

W tym artykule:

What is OEM?

An Original Equipment Manufacturer (OEM) produces products based on the design specifications provided by another company. In this model, the buyer keeps control over the product’s design, branding, and intellectual property. The OEM’s role is to manufacture the product according to the company’s exact requirements.

OEM Examples:

For example, a medical device company might partner with a custom LCD manufacturer, such as Newhaven Display, to produce a custom LCD screen with specific size, brightness, voltage, and interface requirements. The medical device company controls the overall design and branding, while Newhaven Display manufactures the display to these precise specifications.

Another example is Foil, Inc., which collaborated with Newhaven Display to create a sunlight-readable 2.4” TFT LCD for the controller of their innovative electronic surfboard. This display ensures clear visibility in bright outdoor conditions. Learn more about the project here.

A typical car is also built with hundreds of OEM parts, including shocks, seats, tires, and the air conditioning compressor, each often produced by different original equipment manufacturers.

Key Features of OEM:

- Design ownership: The buyer provides detailed designs and technical specifications to the manufacturer, allowing for total creative control over the product's design.

- Customization: OEMs can build products to any specification, offering flexibility not found with ODMs.

- Unique brand: The products are branded with the buyer's name, increasing their uniqueness.

- Intellectual property flexibility: Working with an OEM means fewer intellectual property restrictions, making it easier to switch manufacturers if needed.

Learn more: History of Touchscreens, Types, & How They Work

Benefits of Working With OEMs

- Full customized solutions: OEMs create components specifically tailored to meet precise specifications, allowing for unique product differentiation and brand alignment.

- High quality and reliability: OEMs typically produce components with rigorous quality control, ensuring reliability and longevity that align with brand standards. At Newhaven Display, we uphold these principles through stringent testing and certified manufacturing processes. Explore our quality standards and certifications.

- More brand control: By partnering with an OEM, companies maintain full control over the branding, design, and features of the final product.

- Stronger intellectual property protection: Working with an OEM often allows for tighter IP control, as the product is designed specifically for your brand rather than a more generic model.

- Specialized expertise: OEMs bring in-depth expertise in their specific components, ensuring advanced and efficient solutions tailored to industry standards.

- Long-term supplier relationship: An OEM partnership often leads to a stable and strategic supplier relationship, enabling smoother collaboration on future projects and new product developments.

OEM Disadvantages

- IP risks without robust agreements: Without comprehensive agreements, there is a risk of IP theft or reverse engineering. OEMs may have the capability to market similar products under their brand, emphasizing the need for clear, enforceable IP protections in the partnership.

- Cost: Working with OEMs can involve higher costs due to custom specifications, maintaining quality standards, and investments in research and development (R&D) needed to create unique products.

- Time to market: OEMs often require longer lead times since the buyer manages the design and development process. This can delay the time to market compared to ODMs, which offer ready-made solutions.

What is ODM?

An Original Design Manufacturer (ODM) designs and manufactures products that are then sold to other companies for rebranding. ODMs typically have their own product designs, which companies can adopt with minimal modifications. This model is often chosen by businesses looking for quick time-to-market solutions or those without the expertise to design their own products.

ODM Examples:

A company may need a standard display for its electronic device but does not require customization. The ODM provides an off-the-shelf design that the company can rebrand and integrate into its product with minimal changes. Similarly, a company introducing a line of kitchen appliances may partner with an ODM that offers pre-designed products like microwaves, blenders, or coffee makers. The ODM handles product design and manufacturing, allowing the company to focus on branding and marketing.

Key Features of ODM:

- Design provided by the manufacturer: The ODM is responsible for product design, with the buyer making slight modifications if needed.

- Faster production: Since designs are pre-made, buyers can bring products to market faster.

- Cost-effective: ODM products are often cheaper because design and development costs are spread across multiple clients.

Learn more: Nits vs Lumens vs Luminance

Benefits of Working With ODMs

- Faster time to market: ODMs have established supply chains and manufacturing processes, allowing for quicker product development and launch.

- Reduced development costs: By leveraging an ODM's expertise and resources, you can significantly reduce upfront development costs.

- Scalability: ODMs can quickly scale production to meet increasing demand, allowing you to capitalize on market opportunities.

- Reduced risk: By transferring some of the manufacturing and supply chain risks to the ODM, you can mitigate potential challenges.

- Focus on core competencies: Partnering with an ODM allows you to focus on your core business activities, such as marketing, sales, and customer service.

ODM Disadvantages

OEM vs. ODM: Which is Right for You?

An OEM builds products strictly following the customer’s design, allowing full customization. An ODM, on the other hand, creates and manufactures products based on their own designs, which customers can minimally customize or rebrand for resale.

OEM vs ODM Side-by-Side Table

| Aspect | OEM | ODM |

|---|---|---|

| Design | Customer provides the design. | Manufacturer provides the design. |

| Customization | Fully customizable. | Limited customization. |

| Ownership | Customer owns the design and intellectual property. | Manufacturer often retains design ownership. |

| Koszt | Higher initial investment. | Lower upfront cost. |

| Time to market | Longer due to development and design phases. | Faster with ready-made designs. |

| Expertise needed | Requires customer expertise in design. | Minimal customer expertise required. |

| Flexibility | High, tailored to specific needs. | Limited to existing designs. |

| Risk | Higher due to development complexity. | Lower due to proven designs. |

Which to Choose?

Choosing between an OEM and ODM depends on your business goals and resources. If you need a fully customized product and have the expertise and budget to develop a design, an OEM is the better choice. However, if speed to market, cost savings, and a ready-made solution are priorities, an ODM may be the more practical option.

Ostatnie posty na blogu

-

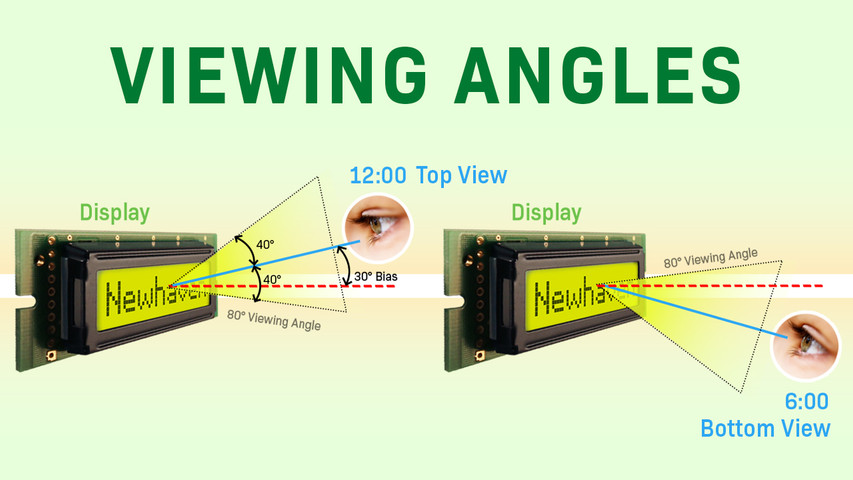

Understanding Display Viewing Angles

Have you ever found it difficult to read an ATM screen from the side or noticed how a display appear …Feb 4th 2025 -

OEM vs ODM Manufacturing - Differences, Benefits, and Limitations

When outsourcing manufacturing, two terms come across: OEM (Original Equipment Manufacturer) and …Nov 26th 2024 -

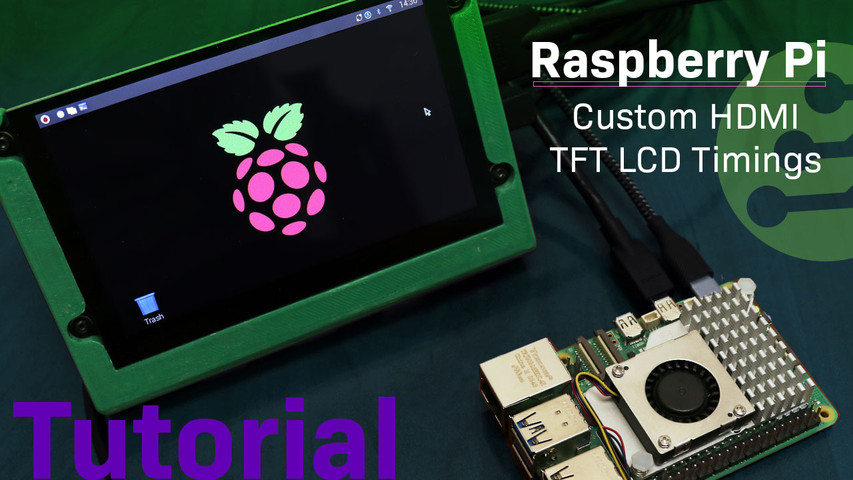

Raspberry Pi Custom HDMI TFT LCD Timings

Setting up custom timing for HDMI TFTs and Touch HDMI Displays on Raspberry Pi can significant …Oct 29th 2024