Optical Bonding Solutions

Increase display performance and durability with our advanced optical bonding services. Perfect for demanding environments, our solutions deliver exceptional visual quality where it matters most.

Get startedOptically Bonded LCD & OLED Custom Displays

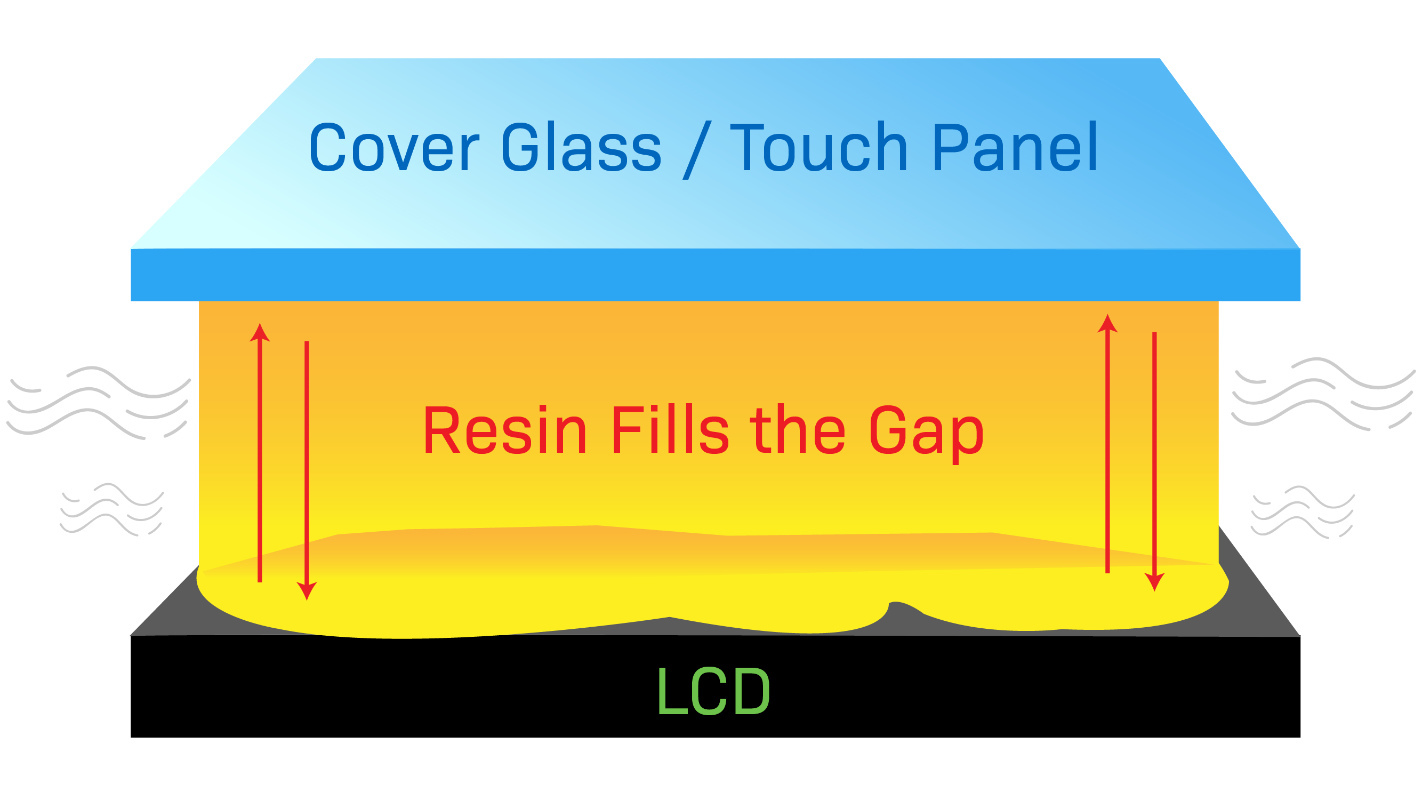

Our custom displays with optical bonding improve display readability by reducing reflections and enhancing contrast. We achieve this by filling the air gap between the display and cover glass with an advanced optically clear adhesive. This minimizes the parallax effect and internal light reflections, resulting in a clearer, brighter image. Whether you are designing for industrial, medical, marine, automotive, agriculture, or military applications, our custom-engineered solutions ensure that your displays are more readable, durable, and resistant in the most demanding environments.

Why Choose Optical Bonding?

- Improves vibration & shock display resistance.

- Reduces glare and improves color accuracy.

- Protects the display from dust and moisture.

- Delivers a clear image from any angle.

- Prevents condensation and improves display performance in harsh environments.

Our Optical Bonding Capabilities

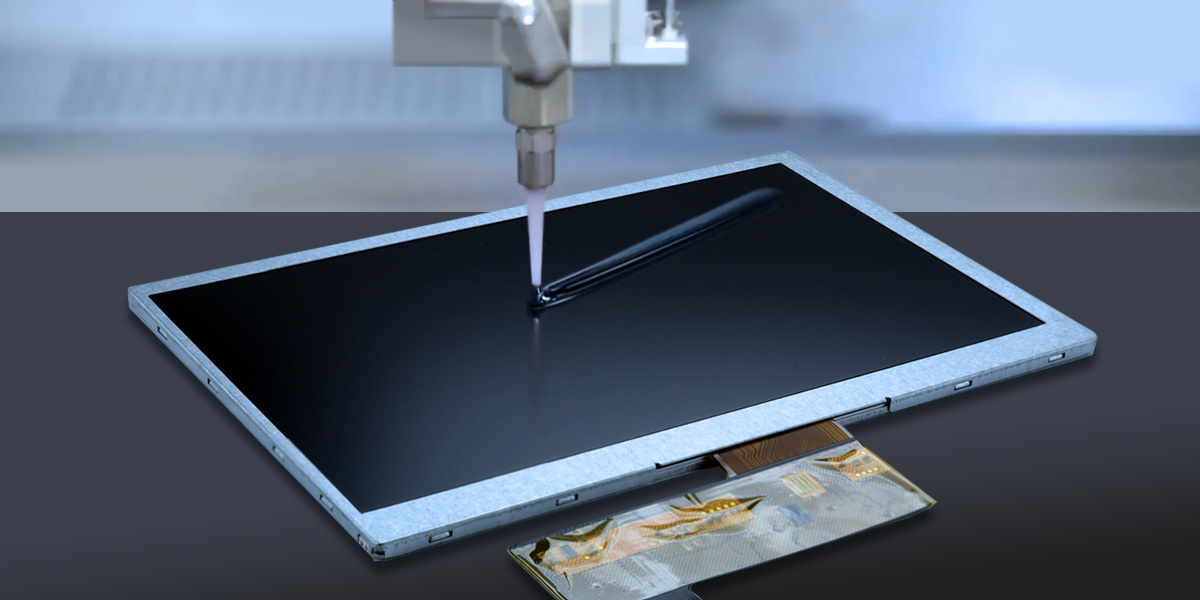

Dry or Liquid Optical Bonding

Our advanced manufacturing capabilities offer both dry and liquid optical bonding techniques to accommodate a wide range of display requirements. Utilizing quality manufacturing processes, we precisely apply optical adhesives to reduce air gaps between the display and cover glass. This high-precision screen bonding is tailored for diverse industry needs, ensuring consistent quality and superior durability, regardless of environmental conditions.

Learn more about optical bonding

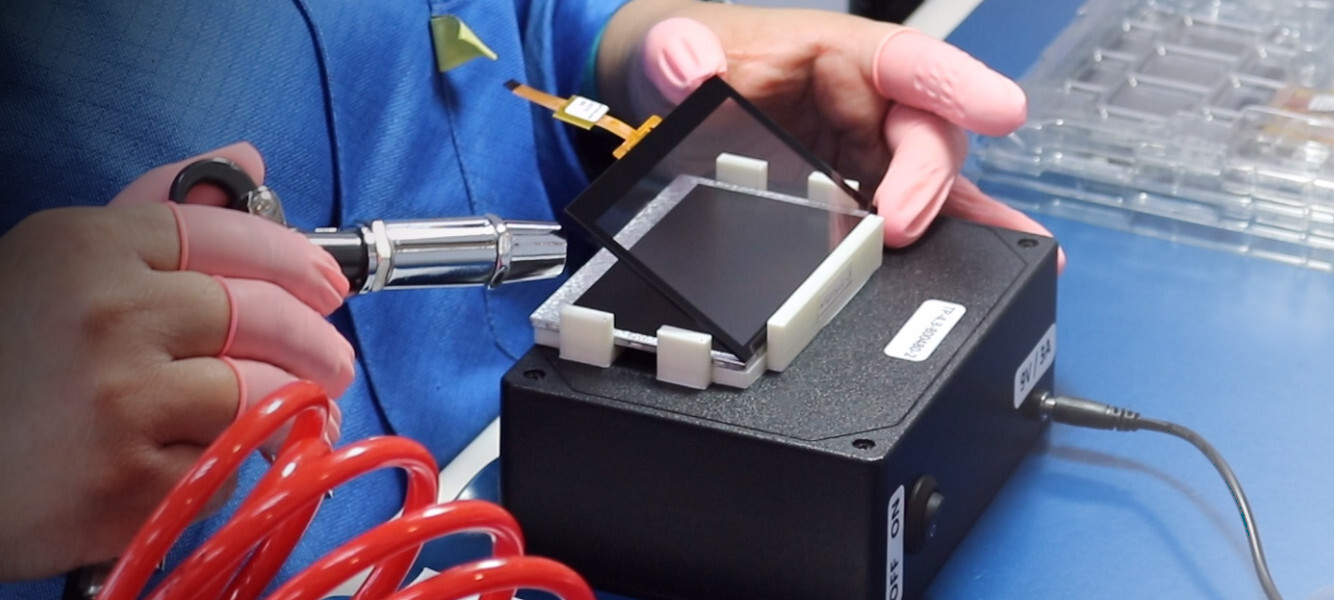

Perimeter Bonding

Our perimeter bonding technology provides dependable sealing solutions for displays, with a focus on precise edge protection. We use specialized equipment to apply perimeter seals that protect against external factors like dust and moisture. This method is a highly efficient and cost-effective alternative when full optical bonding is not required.

ISO-Certified Quality for Consistent Performance

Our production facilities maintain consistent quality guidelines and our certifications ensure top-quality products and safe operating conditions.

ISO 9001:2015 / ISO 14001 / ISO 13485 / TS-16949 / ISO 13485

Our certificationsWith advanced manufacturing processes, rigorous testing, and comprehensive inspection, we don’t just assure quality—we embed it into every component.

Normas de calidad

Engineered Precision Bonding with Complete Display Customization Options

Our display manufacturing approach to optical bonding helps us deliver high-performance and durable LCD and OLED solutions for the most demanding applications. In addition to display bonding, we offer a comprehensive range of customization options, from specialized coatings to custom shapes and sizes, providing complete, end-to-end solutions tailored to your display needs.

- High transparency adhesives

- Customizable thickness

- UV and heat resistant

- Custom display sizes and shapes

- Anti-glare, anti-reflective, and anti-fingerprint coatings

- Edge-to-edge bonding for sleek, modern designs

Explore our full custom display options

High-Performance Display Bonding Solutions for Every Industry

Our optical bonding solutions are trusted across a wide range of industries where exceptional display performance is critical. We serve industries such as medical and healthcare, industrial equipment, marine and vending, agriculture, automotive, transportation, military and defense, and consumer electronics.

ComenzarFrequently Asked Questions

Explore a collection of the most commonly asked questions to gain insights and solutions that can help streamline your experience.

Explore our complete Custom Display FAQ

Need assistance or have questions about display customizations?

Contact an engineerOptical bonding involves applying a layer of adhesive between the display and cover glass to eliminate air gaps, reduce reflections and improve display clarity. It's important because it enhances the display's readability, durability, and performance, especially in challenging environments.

Industries such as medical, military, automotive, marine, and industrial equipment benefit greatly from optical bonding due to the need for durable, clear, and reliable displays in challenging conditions.

Optical bonding can be applied to most types of displays, including LCD and OLED. However, it's essential to consult with our experts to ensure compatibility with your specific display and application.

Optical bonding involves applying an adhesive layer across the entire display surface, enhancing clarity and durability. Perimeter bonding, on the other hand, seals only the edges of the display, providing protection from dust and moisture but without the enhanced optical benefits.

Optical bonding enhances touchscreen sensitivity by reducing the parallax effect and improving the accuracy of touch inputs, leading to a more responsive and precise user experience.

Don't Settle for Standard

Solicite una solución de exposición personalizada

Contact us today to learn more about how our LCD and OLED optical bonding services can enhance your displays. We’re ready to help you find the perfect solution tailored to your application needs.