Klejenie optyczne: zalety i zastosowania

7 lutego 2024 r.

Wiele zastosowań, zwłaszcza w trudnych warunkach środowiskowych, wymaga specjalnych modyfikacji wyświetlaczy elektronicznych w celu poprawy ich trwałości i widoczności przy jednoczesnym ograniczeniu odblasków i kondensacji. Jednym ze sposobów poprawy wszystkich tych aspektów jest zastosowanie klejenia optycznego.

W tym artykule:

Czym jest klejenie optyczne?

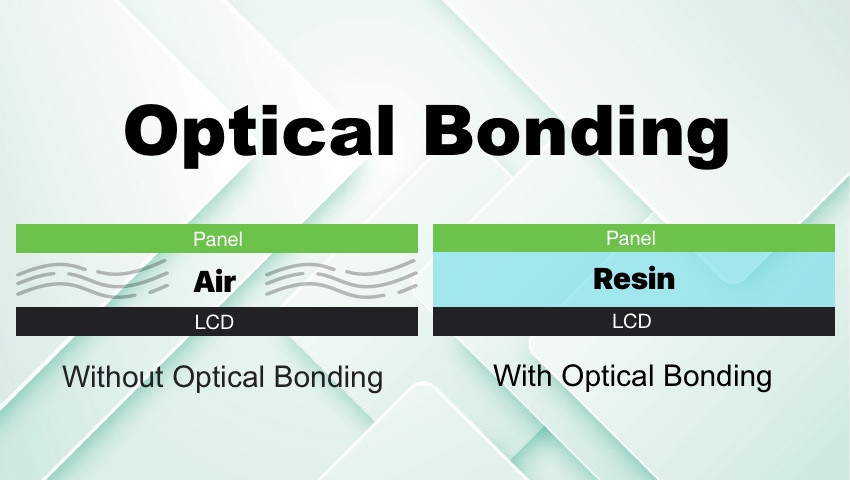

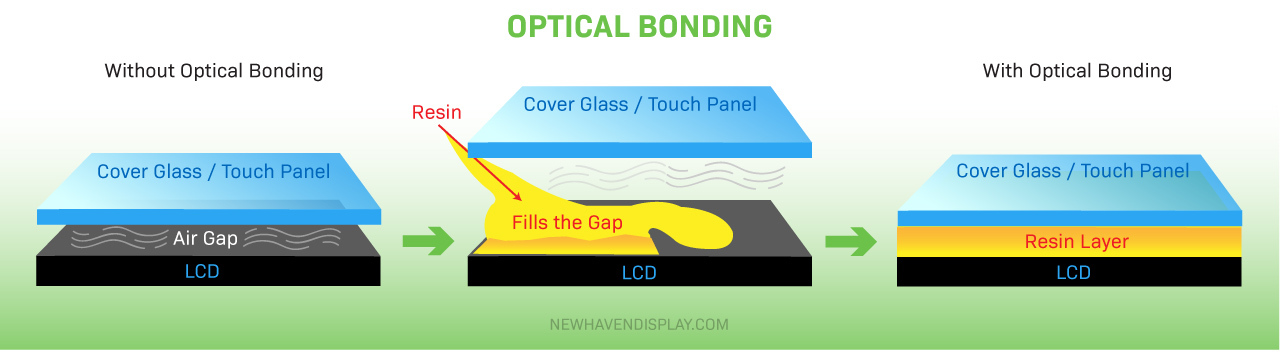

Klejenie optyczne to proces bezpośredniego przyklejania ochronnej osłony szklanej lub plastikowej do ekranu wyświetlacza, takiego jak panel LCD lubOLED, za pomocą specjalnej warstwy kleju. Ta warstwa kleju, która zazwyczaj jest wykonana z silikonu, żywicy epoksydowej lub uretanu, zastępuje zwykłą szczelinę powietrzną, która występuje między wyświetlaczem a szkłem ochronnym.

Klejenie optyczne zwiększa trwałość i widoczność wyświetlacza, jednocześnie zmniejszając odblaski i kondensację, szczególnie w warunkach zewnętrznych, gdzie wilgoć, wiatr, światło słoneczne i inne czynniki mogą wpływać na działanie wyświetlacza.

Dowiedz się więcej:Różnica między wyświetlaczami OLED i LCD

Rodzaje łączenia optycznego

Istnieją dwa rodzaje łączenia optycznego: łączenie na mokro i łączenie na sucho.

- Klejenie na mokro: Wykorzystuje się płynną, optycznie przezroczystą żywicę (OCR), znaną również jako LOCA (Liquid Optical Clear Adhesive), która wypełnia szczeliny i utwardza się, tworząc stałą substancję.

- Klejenie na sucho: Wykorzystuje wstępnie uformowany, stały, optycznie przezroczysty klej (OCA) w celu uzyskania trwałego połączenia. Istnieją dwie główne odmiany klejenia na sucho:

- Tradycyjne klejenie na sucho: Metoda ta wykorzystuje ciepło i ciśnienie do aktywacji kleju, co jest zazwyczaj szybsze i bardziej opłacalne niż klejenie na mokro, ale może sprawiać trudności w przypadku nierównych powierzchni.

- Klejenie na sucho utwardzane promieniowaniem UV: Klejenie na sucho utwardzane promieniowaniem UV polega na użyciu wstępnie przyciętego arkusza kleju znanego jako klej samoutwardzalny (SCA) lub UV-OCA, który twardnieje pod wpływem promieniowania ultrafioletowego (UV).

Materiały stosowane do łączenia optycznego

Dostępne są różne rodzaje klejów, a wybór konkretnego zależy od konkretnych wymagań i potrzeb zastosowania. Najpopularniejsze rodzaje klejów do łączenia optycznego to silikonowe, epoksydowe, akrylowe i poliuretanowe.

- Krzem: Krzem jest szeroko stosowany jako klej, ponieważ jest elastyczny, odporny na wysokie temperatury oraz pochłania wstrząsy i wibracje. Charakteryzuje się również dobrą przezroczystością optyczną i nie żółknie z upływem czasu, co pomaga zachować klarowność obrazu wyświetlacza. Jednak podczas pocierania krzem może wytwarzać zanieczyszczenia na krawędziach, co sprawia, że w zastosowaniach takich jakekrany dotykowe konieczna jest ochrona krawędzi.

- Żywica epoksydowa: Żywica epoksydowa charakteryzuje się lepszą odpornością na wysoką temperaturę i zapewnia mocniejsze połączenie niż silikon, dzięki czemu idealnie nadaje się do zastosowań wymagających wysokiej precyzji i konstrukcji. Jednak po związaniu nie można jej ponownie przetwarzać. Wymaga również ostrożnego nakładania, ponieważ bardzo szybko utwardza się.

- Akryl: Materiał ten nadaje się do szybkich procesów produkcyjnych, ponieważ utwardza się pod wpływem promieniowania UV. Może jednak mieć niższą odporność na ciepło niż inne opcje i może nieznacznie kurczyć się podczas utwardzania, co wymaga precyzyjnego nakładania.

- Poliuretan: Kleje poliuretanowe są odporne na ekstremalne warunki, ale są droższe niż inne opcje, takie jak silikon i żywica epoksydowa. Pod wpływem światła mają tendencję do żółknięcia z upływem czasu.

Jaki materiał jest najczęściej stosowany do łączenia optycznego w wyświetlaczach LCD?

Najczęściej stosowany przez producentów wyświetlaczy materiał do klejenia optycznego w wyświetlaczach LCD zależy od konkretnego zastosowania i pożądanych właściwości, ale dwa najpopularniejsze to silikon i akryl.

Dowiedz się więcej:Różnica między nitami, lumenami i luminancją

Proces nakładania kleju optycznego

- Przygotowanie: Panel wyświetlacza i szkło ochronne są dokładnie czyszczone w celu usunięcia kurzu i innych cząstek.

- Nakładanie kleju: Warstwa suchego lub płynnego kleju jest nakładana na panel wyświetlacza lub wewnętrzną powierzchnię szkła ochronnego.

- Klejenie: Szkło ochronne jest starannie wyrównane i umieszczone na panelu wyświetlacza, a klej jest utwardzany za pomocą światła UV lub ciepła, tworząc trwałe połączenie.

- Kontrola: Klejony wyświetlacz jest sprawdzany pod kątem jakości, aby upewnić się, że nie ma pęcherzyków powietrza ani przesunięć.

Powiązane:Jak czyścić wyświetlacz elektroniczny

Zalety klejenia optycznego

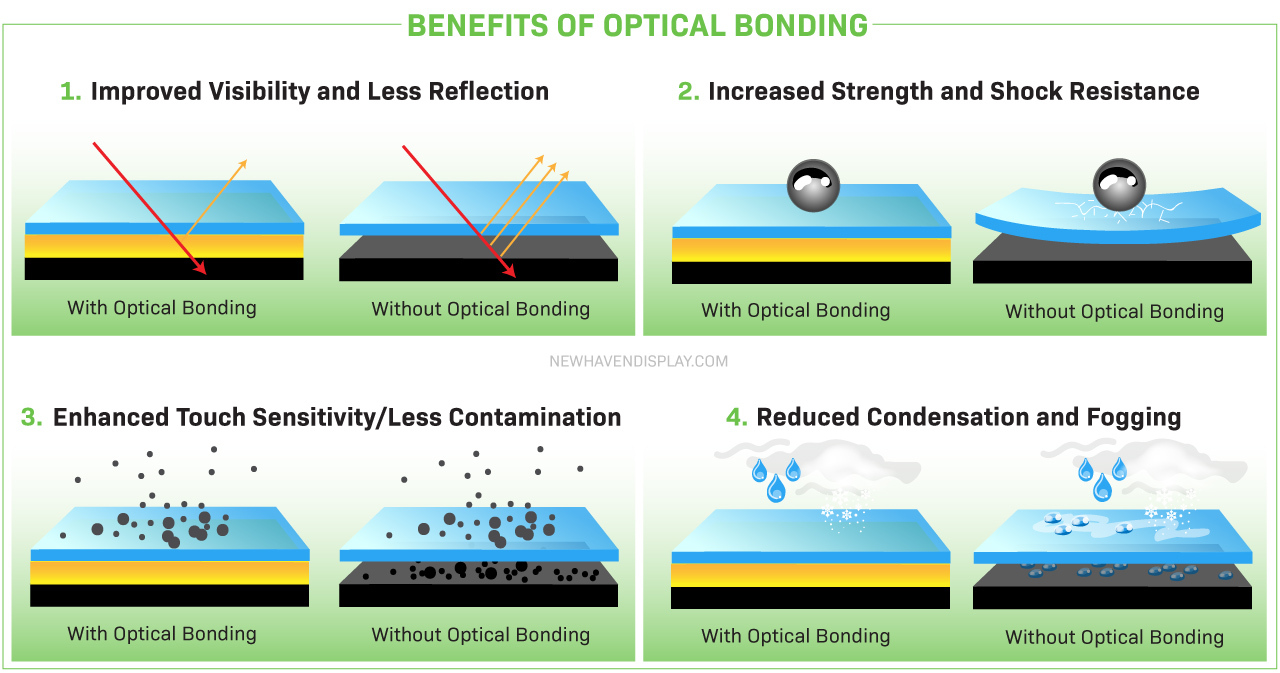

- Lepsza widoczność i mniejsze odbicia: Klejenie optyczne eliminuje szczelinę powietrzną, co zmniejsza odbicia i załamania światła. Prowadzi to do znacznego zmniejszenia odblasków i poprawia czytelność wyświetlacza w różnych warunkach oświetleniowych.

- Zwiększona wytrzymałość i odporność na wstrząsy: warstwa klejona zwiększa wytrzymałość konstrukcyjną wyświetlacza, dzięki czemu jest on bardziej odporny na wstrząsy, wibracje, wilgoć i kurz. Oznacza to, że wyświetlacz może wytrzymać trudne warunki środowiskowe bez uszkodzeń.

- Zwiększona czułość dotykowa/mniej zanieczyszczeń: W przypadku wyświetlaczy dotykowych klejenie optyczne poprawia czułość i dokładność interfejsu dotykowego, zapewniając płynniejsze działanie.

- Zmniejszona kondensacja i zaparowanie: W środowiskach o zmiennych temperaturach klejenie optyczne zapobiega kondensacji i zaparowaniu wyświetlacza.

Dowiedz się więcej: Jakie są różnice między wyświetlaczami transmisyjnymi, refleksyjnymi i transfleksyjnymi?

Zastosowania klejenia optycznego

Klejenie optyczne poprawia wydajność wyświetlacza, widoczność i trwałość w trudnych warunkach i ekstremalnych temperaturach. Niektóre z najczęstszych zastosowań klejenia optycznego obejmują:

- Elektronika użytkowa: Klejenie optyczne jest szeroko stosowane w urządzeniach przenośnych, takich jak smartfony, tablety i laptopy, w celu poprawy czytelności i trwałości wyświetlacza.

- Wyświetlacze samochodowe: Klejenie optyczne ma zasadnicze znaczenie w przypadku desek rozdzielczych, zestawów wskaźników i systemów informacyjno-rozrywkowych, ponieważ jest odporne na ekstremalne temperatury.

- Urządzenia medyczne: Klejenie optyczne jest stosowane w wyświetlaczach medycznych do sprzętu diagnostycznego, monitorów chirurgicznych i systemów monitorowania pacjentów w celu poprawy widoczności i zmniejszenia ryzyka zanieczyszczenia.

- Wyświetlacze przemysłowe: Klejenie optyczne jest stosowane w urządzeniach automatyki przemysłowej, interfejsach człowiek-maszyna (HMI) i innych wytrzymałych zastosowaniach.

- Wyświetlacze zewnętrzne: Ta metoda łączenia doskonale nadaje się do stosowania w cyfrowych znakach, kioskach i innych wyświetlaczach zewnętrznych. Zapewnia lepszą czytelność w jasnym świetle słonecznym i zwiększoną trwałość, nawet w trudnych warunkach pogodowych.

- Wyświetlacze wojskowe i lotnicze: Klejenie optyczne jest stosowane w wyświetlaczach wojskowych i lotniczych w celu zwiększenia trwałości i niezawodności w trudnych warunkach.

Czy w ekranach dotykowych stosuje się klejenie optyczne?

Klejenie optyczne jest szeroko stosowane do łączenia paneli ekranów dotykowych i wyświetlaczy w celu poprawy widoczności wyświetlacza, odporności na wstrząsy i czułości dotykowej.

Wniosek

Klejenie optyczne to skuteczne rozwiązanie poprawiające klarowność, trwałość i funkcjonalność ekranów wyświetlaczy. Technika ta jest stosowana w wielu branżach i zastosowaniach, a materiały klejące i rodzaj procesu klejenia zależą od indywidualnych wymagań i środowiska każdego zastosowania.

Masz pytania lub chcesz opracować niestandardowe rozwiązanie wyświetlacza z klejeniem optycznym? Skontaktuj się z nami, aby rozpocząć tworzenie niestandardowego rozwiązania wyświetlacza.