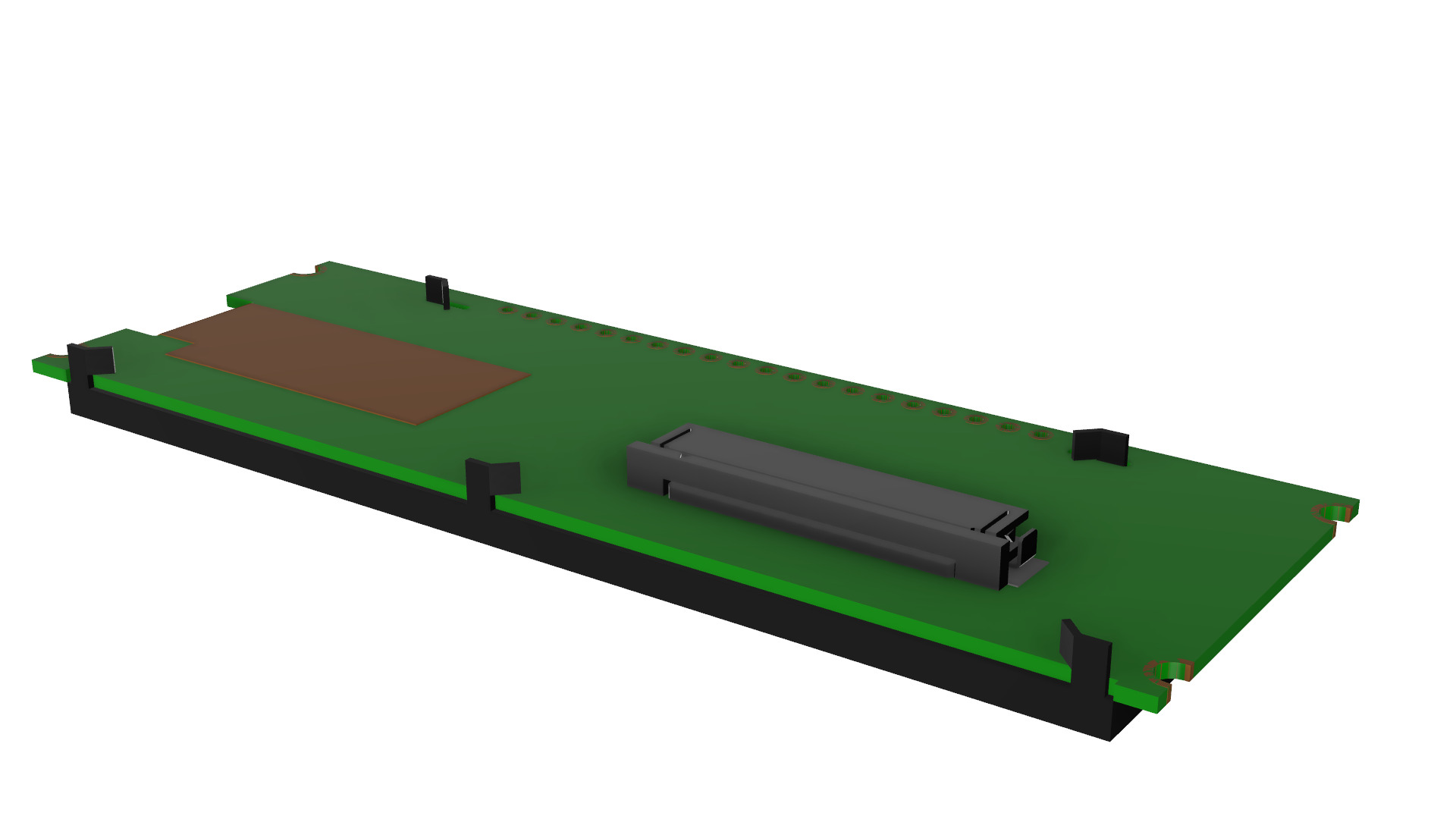

A2001WV-S-2P SMT | Two Pin Backlight Connector | Vertical Connector | Surface Mount Connector

This 2 Pin, surface mount backlight connector is a display accessory that connects quickly and easily with display backlights. The connector is made of Nylon material with a 2 mm pitch housing. The current rating for this vertical connector is 2A, and its voltage rating is 100VAC. Designed to handle extreme environments, this model has a flammability rating of UL94V-0 and operates exceptionally well within a temperature range of -40°C to 105°C. The accessory is also RoHS and REACH compliant.

Vertical Backlight Connector Specifications

| Number of Positions: | 2 Position |

| Pitch: | 2 mm |

| Number of Rows: | 1 Row |

| Mounting Angle: | Vertical |

| Contact Gender: | Pin (Male) |

| Contact Material: | Brass |

| Contact Plating: | Tin |

| Housing Material: | Nylon |

| Dimmensions: | 2 mm x 8 mm |

| Housing Color: | White |

| Operating Temperature: | -40°C ~ 150°C |

| Flammability Rating: | UL 94V-0 |

| Current Rating: | 2 A |

| Voltage Rating: | 100V AC,DC |

| Insulation Resistance: | 1000 MOhms |

Display Custom Solutions

Quality Standards

At Newhaven Display we strive every day to provide our customers with the highest quality products. This means Quality, Engineering, and Manufacturing teams are aligned to exceed your expectations.

Our customers should expect their products to meet or exceed the following standards:

All Products

| Reliability Testing | Customers can expect all production parts to meet or exceed operational requirements over temperature, humidity, and vibration. |

| Glass Cleanliness | Customers can expect glass to be protected by liners and presented mindful of cleanliness standards. This means glass will be clean of contaminants, fingerprints, and other foreign material. |

| Bezel Appearance | Bezels will be uniformly painted free of foreign materials and distracting cosmetic blemishes. Our standards maintain a clean scratch-free surface. |

| PCB Appearance | PCB’s are delivered with long-term reliability in mind. Finishes are free of bubbles, foreign contaminants, and meet all UL fire requirements. PCB materials will always be delivered within industry norms. PCB edges will be cleanly cut and void of burrs. |

| Soldering | Soldering of all leaded and SMT components is consistent in providing the mechanical security and electrical connectivity. |

| Consistency | Our manufacturing and inspection processes ensure product consistency from lot to lot. This means orders processed over the years will continually meet your expectations. We do this by exacting manufacturing specifications, with attention to detail in our processes, and by comparing to the golden units. |

| Product Integrity | Quality in product manufacturing ensures integrity in construction. Customers can expect tight assembly without worry of loose parts or missing material. Our products will meet all environmental expectations including temp, humidity, & vibration conditions. |

| Glass Color | While normal variations of glass color may occur (due to manufacturing tolerances), Newhaven Display maintains color compliance per internal approved color charts. These charts are maintained to ensure any minor glass deviations are identified and corrected as needed. |

| ESD Protection & Safety | All devices are designed and handled in consideration of ESD protection. This includes ESD-SAFE packaging within anti-static bags, wraps, and trays. Customers are reminded to always follow ESD safety to best protect the devices. |

Our Distributors

Newhaven Display partners with distributors worldwide to bring you the best products and design services, no matter where you are working from.