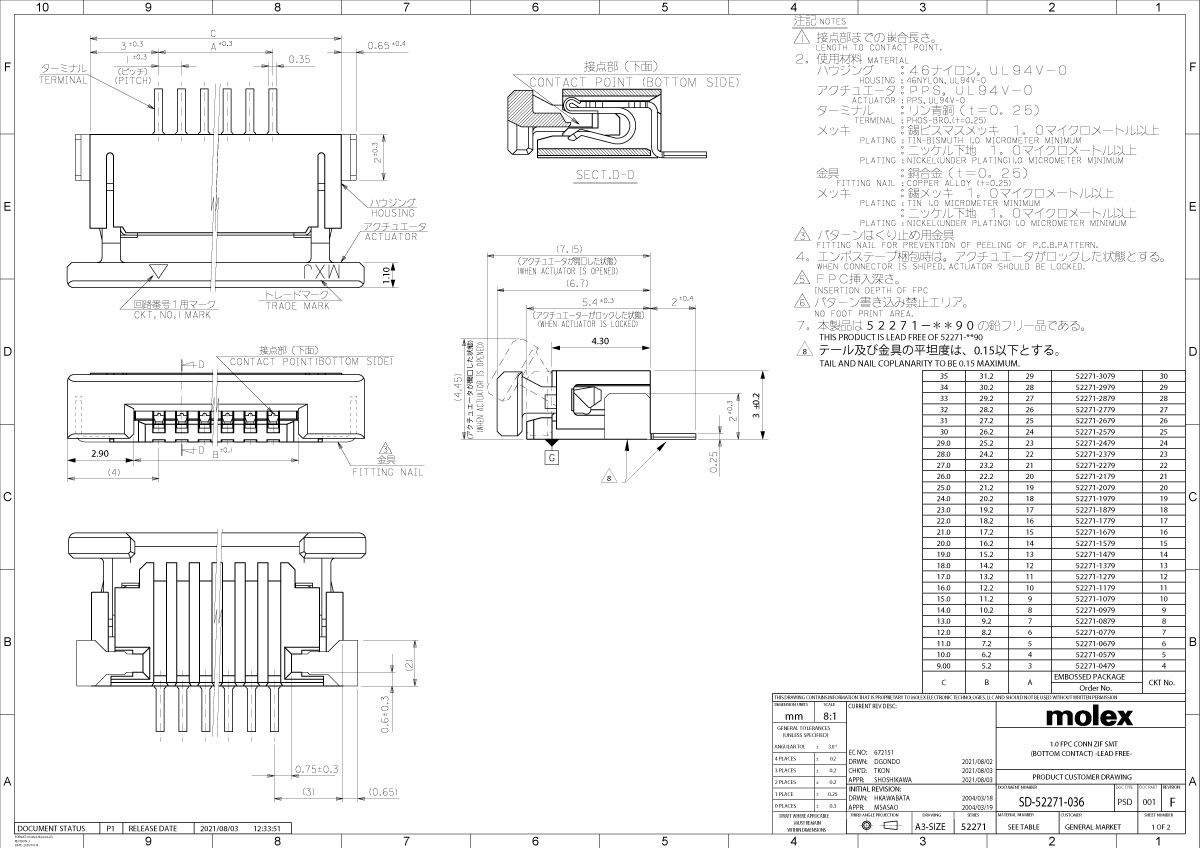

Sturdy 6 Circuit Easy-On Molex FFC/FPC Connector

Optimized for both reliability and simplicity, the Molex_52271-0679 is a strong candidate for connecting 6 circuit FFC or FPC cables to your board. It utilizes surface mounting and includes a right-angle layout to manage cables cleanly in designs and prototypes. The connector has tin-plated phosphor bronze contacts with a 1mm pitch and is rated for operation between -40 and 85°C, making it suitable for applications where a reliable connection in demanding environments is needed.

Molex_52271-0679: Technical Specifications

| Circuits | 6 |

|---|---|

| Pitch | 1mm |

| Positions | Bottom Contact |

| Actuator Type | Slider |

| Height | 3mm (Mated) |

| Net Weight | 354.144/mg |

| Mounting Angle | Right Angle Surface Mount |

| Flat Flex Type | FFC, FPC |

| Contact Material | Phosphor Bronze |

| Contact Plating | Tin-Bismuth |

| Housing Color | Natural |

| Operating Temperature | -40° ~ 85°C |

| Flammability Rating | UL 94V-0 |

| Current Rating | 0.5A |

| Voltage Rating | 50V AC/DC |