ESD (Electrostatic Discharge)

Have you experienced an unintentional shock whenever you touched a door knob? This phenomenon, called ESD or electrostatic discharge, is a severe problem in the manufacturing and industrial industry.

This article discusses the nature of ESD, its root causes, and how it can be avoided through anti-static protective policies. Controlling ESD begins with understanding static electricity and how it happens.

Static Electricity

Static electricity is an electric charge remaining on the surface of an object caused by induction or friction (contact and separation) of two materials, a phenomenon known as triboelectric charging.

Although triboelectric charging (friction) is the most common way for electrostatic charge to develop, there are other ways, including induction, ion bombardment, or contact with another charged object.

Unlike electricity which is in motion, static electricity is at rest. The static electricity charge remains until it can move away by electrostatic discharge (ESD).

The amount of static electricity produced depends on the area of contact, material properties, contact and separation speed, humidity levels of the surrounding areas, and other factors. Environments where the relative humidity is high create less static electricity.

What is Electrostatic Discharge (ESD)?

ESD is a temporary flow of static electricity buildup between two conductive objects caused by contact or as they approach one another. The flow of charge is evident by the common spark, or ESD discharge we are all familiar with.

Several ESD events are happening all the time that we can't see or feel. On an average day, our bodies accumulate between 1000 V to 3000 V. While it may take 2000 volts for people to feel ESD, electronic component damage can occur with as little as 10 - 30 volts.

ESD is a real problem in many industries and industrial processes including the manufacturing of electronics, explosives, pharmaceutical, printing, textiles, plastics, energy, and many more.

Related: Everything About Electromagnetic Interference (EMI)

What Causes ESD?

ESD is caused by the contact or close proximity of two static electricity-charged objects. For ESD to happen, it first needs an accumulation of static electricity, more commonly caused by friction between two materials (tribocharging).

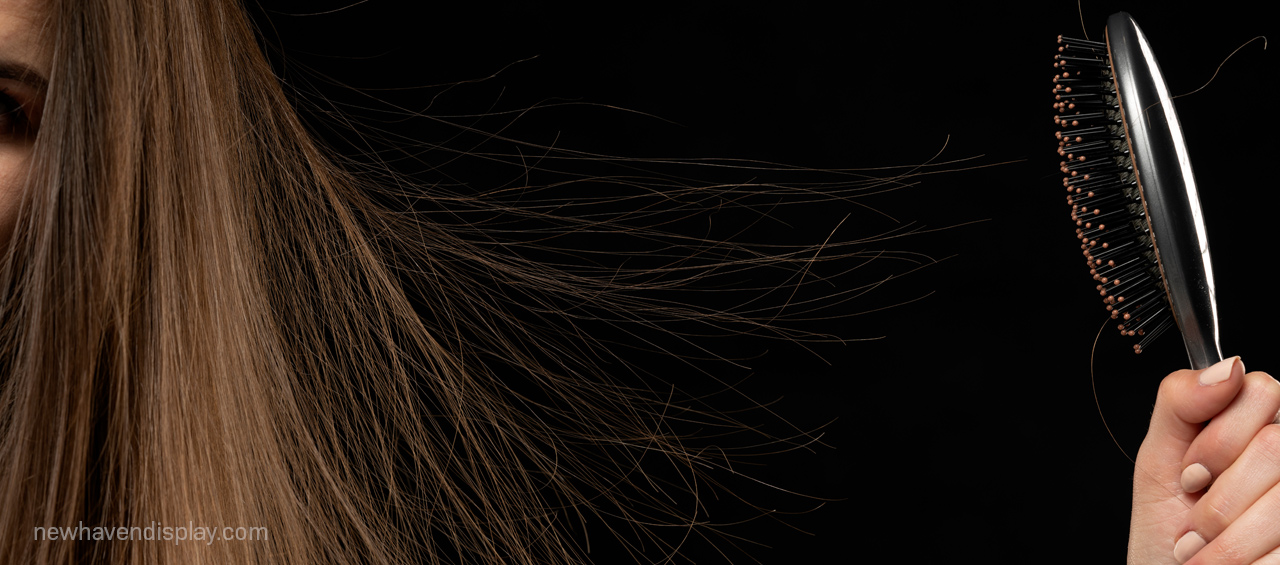

Examples of ESD events include the shock we receive when touching a door knob, shaking hands with someone, removing PVC tape, changing clothes, hair combing, or touching conveyor belts at the store.

ESD Damage

ESD damage can result from handling electronic devices within uncontrolled environments or when inadequate ESD control methods are utilized.

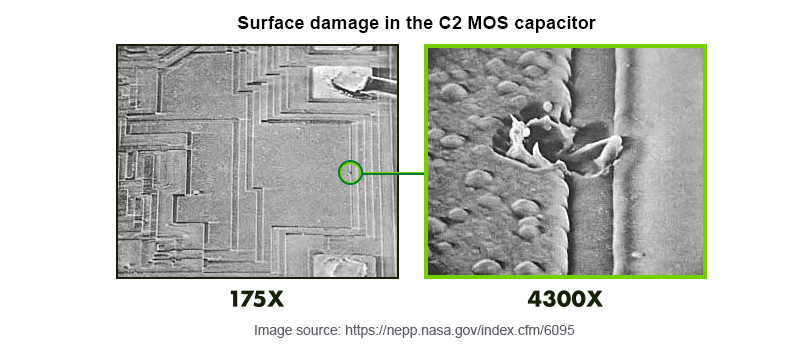

ESD damage can be classified as catastrophic or latent. Catastrophic failure refers to permanent device damage that can sometimes be easily seen, such as sparks, melting, or smoking. The damage is done immediately by virtue of the discharge. Latent damage occurs when a device continues to operate but its lifespan dramatically reduces. The ESD discharge weakened the device thereby decreasing its lifespan accordingly.

Examples of ESD Damage

- Metal melt

- Junction breakdown

- Oxide failure

- Ruptured passivation

- Electrothermal migration

- Splattered aluminum

- Contact spiking

- Dielectric failure

Damage from an ESD incident depends on whether the device can dissipate the electrical charge or withstand the voltage level involved. The level at which an electronic device fails is called its ESD sensitivity.

It's important to incorporate proper ESD control measures throughout a product's lifecycle, including manufacturing, testing, quality inspections, packing, storage, shipping, and handling processes.

Protection From ESD

ESD protection when handling electronic components and devices starts with proper ESD-protected areas. An ESD Protected Area (EPA) is a designated area where all elements, including surfaces, tools, people, and sensitive devices, are protected against static electricity. All elements are grounded and kept at the same electrical potential within this area. This all helps to prevent the build-up of charge thereby reducing the likelihood of ESD discharges.

Related: How to Clean an Electronic Display

The ANSI (American National Standards Institute) and IEC (International Electrotechnical Commission) have defined EPA international standards.

How to Protect from ESD?

Whether you are handling an LCD, soldering a circuit board, or working in an ESD-sensitive manufacturing environment, there are two important factors to consider to protect against ESD:

- Minimize static electricity build-up

- Dissipate it using proper ESD procedures, equipment and tools

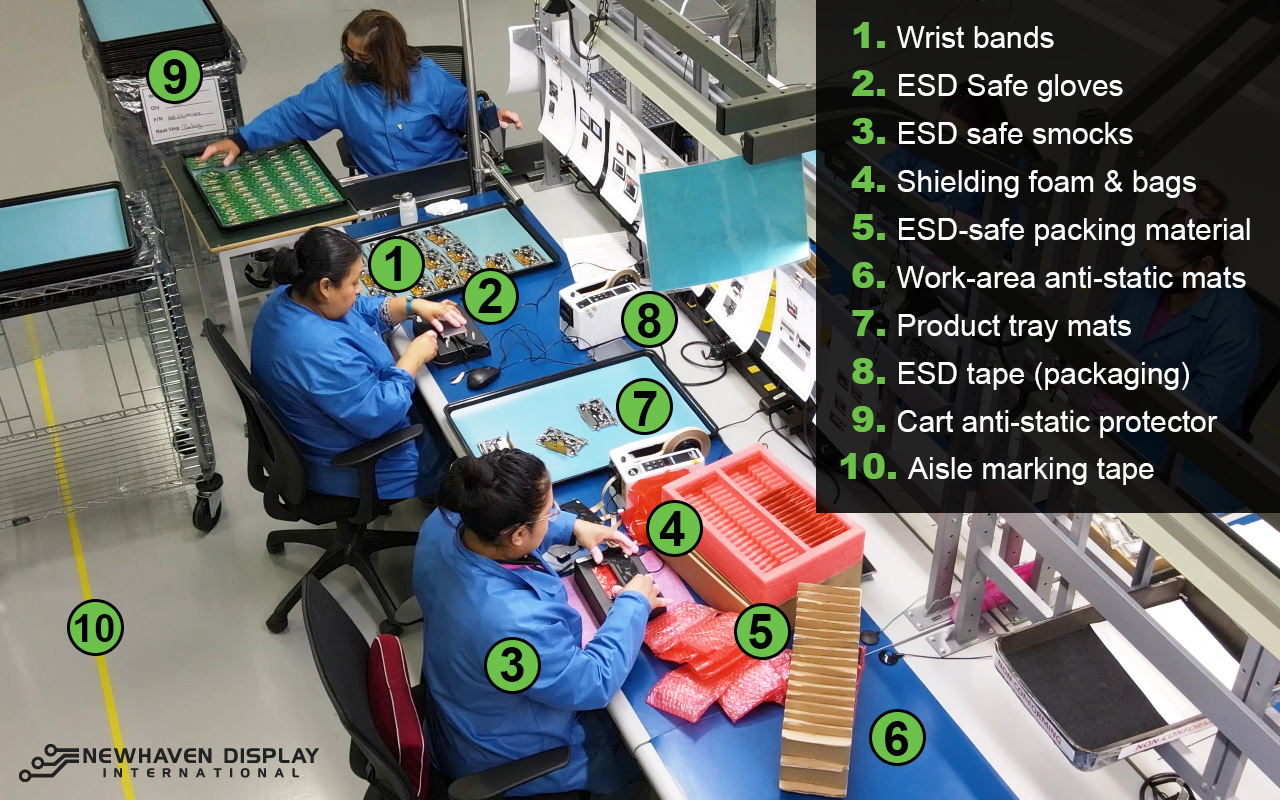

ESD Protection During Manufacturing and Assembly

Electronics manufacturers must follow proper ESD and EPA standards to ensure staff safety and product quality throughout the manufacturing, assembly, storage, and shipping processes.

Related: Newhaven Display Quality Standards

ESD protection in manufacturing and industrial environments follows EPA standards. The main concept of an EPA is to minimize and dissipate static electricity build-up by:

- Defining EPA boundaries (signs, labels, and physical barriers)

- Providing effective ESD equipment - wristbands, mats, gloves, etc.

- Providing static dissipative grounding methods

- Avoiding highly-charging materials in the EPA vicinity

- Installing static dissipative work surfaces

- Controlling humidity levels

- Training staff operating within the EPA

ESD equipment and tools used to protect against ESD

- ESD-safe packing material

- Work area anti-static mats

- Floor mats

- Wrist bands

- Signs and labels

- Foot grounders (shoes)

- ESD safe gloves

- ESD safe Smocks

- Product tray mats

- Cart anti-static protector

- ESD tape (product packaging)

- Aisle marking tape (define EPA)

- Binders and sheet protectors

- Overhead ionizers

- Shielding foam and bags

ESD Protection During Shipping & Storage

ESD-sensitive devices and components must be protected during shipping, handling, and storage. Static electricity build-up can be accumulated during shipping due to product movement and friction. Electromagnetic shielding, antistatic bags, foams, bubble wrap, and appropriate size boxes and packaging are essential to protect devices and components during transit.

ESD Protection During Product Handling

Always follow ESD-safe handling techniques when working with electronic components. Be sure to ground the human body and electric equipment during work. Preferably, use a conductive mat on the table and wear clothing manufactured with conduction processed fiber (a typical lab jacket includes such fibers). Synthetic fiber is not recommended. To reduce the generation of static electricity, be sure the working environment air is not too dry, (50 ‐ 60% relative humidity recommended).

Related: Everything You Need to Know About Display Image Burn-In

Warehouse humidity levels must be controlled during storage, and employees must wear wristbands when handling and packing ESD-sensitive products. Visit our product usage guidelines to learn more about proper electronic display usage and handling.

Conclusion

A successful ESD control plan requires an effective and efficient training program in which everyone involved knows the essential ESD concepts, procedures, and actions to take when working with ESD sensitive devices.

Latest Blog Posts

-

A Guide to TFT Display Interfaces

Display interfaces often get less attention than screen resolution or brightness, but they carry jus …Dec 16th 2025 -

Choosing the Right Display Resolution: A User-Friendly Guide

Display resolution is one of the most defining choices in product interface design. It determines ho …Dec 11th 2025 -

Arduino vs Raspberry Pi vs BeagleBone: Key Features and Differences

If you're working on an electronics project—whether it's for a DIY automated device, a digital sign, …Dec 8th 2025